What is IREC?

IREC, the International Rocket Engineering Competition, is an intercollegiate competition with participants from colleges across the United States and around the globe. The objective is to design, fabricate, and launch a rocket to the exact target altitude for your category. Currently, there are three altitude categories (10k, 30k, and 45k ft) and three motor categories (COTS - commercial off the shelf, SRAD - student researched and developed, and hybrid). Teams may participate in any combination of altitude and fuel categories.

My university's team, the Case Rocket Team at Case Western Reserve University, participates in 30k COTS, but adds complexity to the competition by fabricating our own airframe with custom composites rather than purchasing pre-fabricated composite tubes.

IREC 2025 - Case Rocket Team

Design and Simulation

I was one of two aerostructures leads for IREC 2025, which ran from beginning design in July of 2024 to finalizing assembly and launching the rocket at our competition in June of 2025. During the preliminary design phase, from July to November of 2025, my co-lead and I focused heavily on design and simulation. Preliminary design was performed with OpenRocket, RasAeroII, and FinSim software for stability analysis, altitude and velocity related flight characteristics, and fin-flutter math respectively. Above, a screenshot of the OpenRocket design is shown with the airframe, recovery system, payload, airbrakes actuator, airbrakes superstructure, and motor in place.

Refining the Design

After preliminary design was approved by older and more experienced members of the team, my co-lead continued to refine simulations and I began focusing on manufacturability and logistics. I organized personnel and delegated tasks to ensure proper CAD and drawings were made for every component, as well as ensured that all designed components were in fact manufacturable and not just shapes able to be made in Solidworks. Based on drafted designs, estimates could be made on required stock for manufacturing and man-hours needed for actual fabrication of the design. Final simulations yielded:

-

Maximum Altitude: 31,317 ft

-

Maximum Velocity: ~ 1980 ft/s, a Mach number of approximately 1.76

-

Stability: 1.7 off the rail, full range 1.7 - 4.7 throughout flight

-

Fin Flutter Velocity: Mach 2.85, FOS = 1.62 > 1.5

-

Maximum Diameter: 5.982 inches

-

Height: 116 inches = 9.677 ft

-

Launch Weight: 76.8 lbs

-

Vehicle Weight: 39.8 lbs

-

Selected Motor: AeroTech O5500-X

-

Maximum Impulse: 4,808 lb-sec

-

Peak Thrust: 1,698 lbs

-

Transition to Manufacturing

Once design was finalized, planned stock orders were updated to reflect potential changes. While we waited for stock to arrive, I had the following tasks

-

create a master manufacturing task-list with stock and order of operations

-

schedule personnel around academic schedules for manual machining

-

schedule personnel around within working hours for composites fabrication

Composite Tubes

I developed a less hands-on required method for handling carbon fiber, with a stand to hold the fabric rather than two individuals holding either end of the roll. 3k weave was selected after cost comparison and handling considerations.During composite fabrication, I accomplished the following:

-

coordination of 10 individuals' schedules across 3 grade-levels to find fabrication times

-

completion of body tube and coupler fabrication within 2 weeks, the fastest in team history of SRAD composites

-

developed younger members' interest in composites

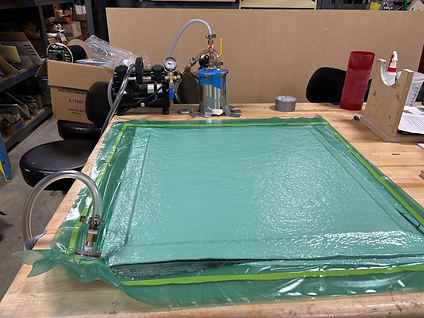

Seen above, there is an image of members conducting a dry hand layup per my instructions with the developed system. This process involved a hollow steel tube being coated in partall paste, sprayed with graphite lubricant, placed on a jig for easy handling, and wrapped in mylar for mold release after layup. Seen on the right, there is an image of me preparing materials (also seen below) for fabricating the blank for our fins, which involves laying up two layers of carbon fiber on either side of a G12 fiberglass sheet, then vacuum bagging so the layup cures under compression (see below to the right).

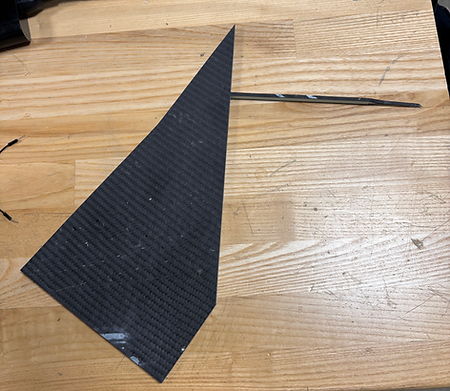

Fin Manufacturing

Once the blank was fabricated and removed from the vacuum bag, we were able to actually machine the fins. This involved using a waterjet to cut the outline of the fin (seen on the right and below) and subsequently using a CNC mill to achieve correct bevel on the fins for most appropriate flight. During this time, I handled a compressed manufacturing schedule resulting from supply-chain delays beyond the team's control and unexpected machine maintenance.

Boattail Manufacturing and Fincan Assembly

Manufacturing the boattail, which I can be seen doing on the right, is my favorite part of the process. This involves 3D-printing a mold in the correct shape for the rocket, completing surface preparation, and subsequently performing a dry hand layup with carbon fiber sleeve rather than weave to account for the changing diameter throughout the geometry. 6k carbon was selected over 3k for increased part stiffness where the first vehicle experienced thrust from the rocket motor.

Fillets and Final Reinforcement

Fillets made of structural epoxy mixed with milled glass fibers were used to properly adhere the fins to the boattail and ultimately create the fincan. This process involved 3D-printing and gluing the fins onto the boattail, sanding the surface for better adhesion, and covering other sections of the fins and boattail (seen above) to prevent spillage from adhering to unwanted parts. Seen on the left, the fillets are poured and flattened before being left to cure. This process is time intensive because including minimum cure time, this is a sixteen-hour process for each of the four sides.

Pictured above and below is the tip-to-tip dry hand layup process, where three layers of carbon fiber are placed on each side to provide additional stiffness to the structure. After each layup, the fincan is vacuum bagged so the layup occurs under compression.

Presentation and Launch

Prior to launch, there were two days of tabling and presentations. During this time, I had the opportunity to explain my team's manufacturing process to many much more experienced rocketeers, and met someone so impressed with the quality of our in-house fabricated composites that he was surprised they were SRAD and not purchased. I'm happy to say that out of 159 teams from around the world, mine placed 13th for the design and build quality of our rocket. Unfortunately, we experienced an off-nominal flight and the vehicle did not survive. Further review found there was likely an issue with the selected motor, as approximately 60% of teams who used the O5500-X faced the same issue. We believe the structure failed at maximum pressure within the rocket, which is an issue the team has never faced and a new design criteria to be brought into IREC 2026 and onward. Despite this, attending the competition and watching our rocket launch was an incredibly fulfilling experience.

President - Case Rocket Team

I was elected for this year-long position in April of 2025 while leading manufacturing of the team's IREC 2025 rocket. I will remain in this position until April of 2026, when the next year's executive board is elected. While in this position, I have done the following:

-

Managed the distribution of a $40,000+ budget across 7 different projects of different sizes.

-

Oversaw budget, personnel, and deliverables for the two largest team projects, IREC 2026 and Composites R+D.

-

Oversaw all general team operations, including technical projects, member recruitment, outreach, and safety.

-

Began process of transitioning team from use of Solidworks to Siemens NX for CAD-based projects.

-

Worked to develop a structure for future projects to be funded and followed through on in later years.

Developmental Engine Testing Intern

GE Aerospace, May - August 2025

Unfortunately, I was not allowed to take pictures at the worksite due to the nature of some work done at the facility. Instead, these are publicly available images of the facility I worked at relating to some of the things I worked on.

I worked at GE Aerospace's Peebles Testing Operation, in Peebles, Ohio over the summer of 2025. I had the opportunity to support the developmental engine testing group with a number of tasks, including the following:

-

Lead a fuel manifold trial fit for a GEnx-2B and successfully prove capability to perform that specific maintenance without removal of the accessory gearbox. Resulting in save several man-hours during on-wing servicing.

-

Conduct multiple cell correlations for the LEAP-1B for data on test stand performance.

-

Complete standard work for engine tests, such as writing and submitting work requests.

-

Navigate old systems to overhaul outdated onboarding documentation.

-

Secured and accepted a return offer for manufacturing engineering in Summer 2026.

IREC 2024 - Case Rocket Team

I joined the Case Rocket Team at the beginning of my first year of college, completed the team's orientation program, and started to actively contribute to the team in November of 2023. The team competed in the 30k COTS category of IREC 2024, the International Rocket Engineering Competition. This was the team's first year using a fully SRAD (student researched and developed) composite airframe. I was heavily involved in composites fabrication, and am happy to say I had a hand in fabricating every SRAD composite component that went onto the rocket.

Nov 2023 - Manufacturing

As this was the team's first year attempting a fully SRAD composite airframe, the first semester was a lot of brainstorming and testing to see what manufacturing methods were viable. Since greater surface area increases drag, we wanted to have as narrow of a diameter for the rocket body as possible to achieve our desired altitude with less difficulty. This required custom molds, which we attempted to manufacture ourselves within a tolerance of

+/- 0.0025 inches across the entire surface. Ultimately, as novice machinists, we were unable to achieve this tolerance across a 30+ inch aluminum tube, and we pivoted to purchasing a tube with similar values to what we were targeting. While unsuccessful, I still developed the following :

-

familiarity with manual milling machines

-

understanding of the importance of tolerances

-

problem-solving with respect to complex fixturing for manual machining

-

familiarity with the general problem-solving process of manufacturing engineering

Jan 2024 - Composite Fabrication

I proved myself capable of competently handling epoxy and performing dry hand layups and was selected to contribute to the following:

-

assist with all composite layups, including nosecone, body tubes, couplers, fins, boattail, and fincan

-

all structural assembly work requiring epoxy use

June 2024 - Attending Competition

For my contributions, I was selected to attend the summer competition and actually had the opportunity to watch the rocket launch. I assisted in handling black powder charges for recovery separation and spoke about our composite fabrication process during the presentation days. We were unfortunately unable to launch until the last day of the competition and subsequently did not receive a score, but following the process from fabrication to launch remains one of my favorite experiences.